When Fastening a Heavy Item to Brick, What Is the Most Important Step?

ane / 8

Buy a Multifariousness of Concrete Screw Lengths

Buy a variety of lengths and then you have the correct spiral size on hand. Select a screw length to penetrate the physical at least ane in. Add ane in. to the thickness of the material yous're attaching to get the minimum length of screw needed. In hard, dumbo materials like physical or stone, this minimum 1-in. screw embedment will work fine. Just for maximum forcefulness, use longer screws, up to 1-three/4 in. embedment, in soft brick or other less dense materials. Y'all may have to experiment with a few unlike lengths to find a screw that yous tin drive fully and that holds securely.

You'll find blue concrete screws at dwelling house centers, hardware stores and lumberyards, or you can order them by phone or on-line. Screws are available in several lengths in packages of 8 or 25 and in boxes of 100. The more you purchase the cheaper the toll. A drill bit is usually included in boxes of 25 or more than. It's worth having a couple of spiral sizes on hand if y'all practise a lot of projects.

2 / eight

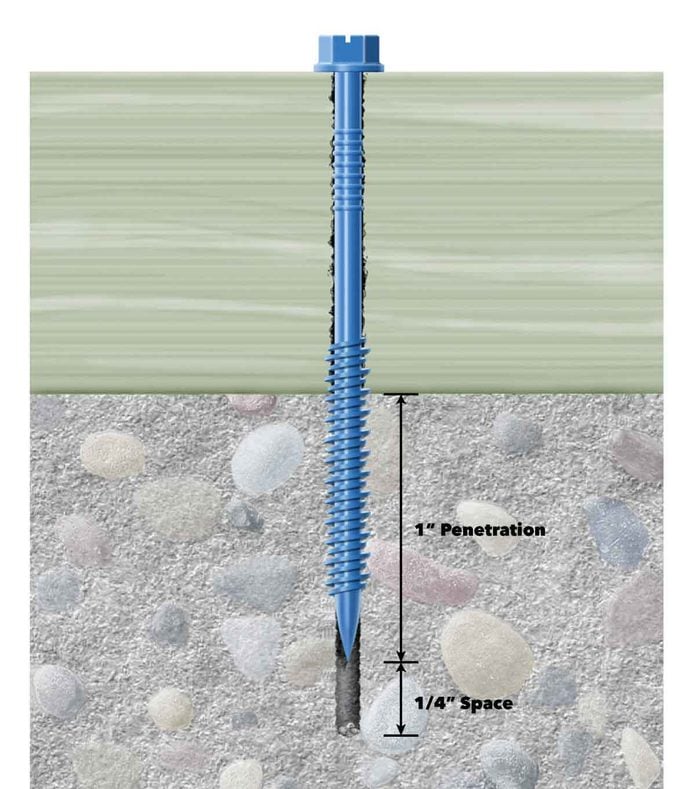

Make Sure to Drill the Hole Deep Plenty

Holes for physical screws should be at to the lowest degree 1/iv in. deeper than the screw will penetrate to allow a little extra space for dust accumulation from the drilling process. Come across the analogy above. Merely it's not always easy to judge how deep you're drilling. Likewise shallow and the screw won't get in. And drilling deeper than necessary is a waste material of time and endeavour. That'southward why most hammer drills come equipped with an adjustable depth stop.

Troubleshooting

If you're having trouble driving the screw all the way, first make sure the hole is deep enough. If it is and yous're however having problem, there's probably also much dust in the hole. Remove the spiral and clean out the hole by running the bit in and out a few times. Try driving the screw again. If information technology's still stubborn, back it out and redrive it a few times. If all else fails, install another spiral a few inches abroad. Finally, consider a little shorter screw for the rest of the holes.

Sometimes you lot'll accept the contrary problem. The spiral volition spin without gripping. If this happens, the material y'all're fastening to is probably as well soft or crumbly. Try a longer spiral, or if you're using a 3/16-in. screw, attempt a 1/4-in. diameter. Yous may accept to apply a physical anchor that expands as you tighten the fastener.

three / 8

Choose iii/16-in. Screws for Most Light- to Medium-Duty Tasks

Home centers and hardware stores stock concrete screws in two diameters, 3/16 in. and ane/4 in. The 3/16-in. diameter screws are plenty strong for most dwelling house tasks similar installing furring strips, screwing down walls to concrete floors, and attaching hardware to block or brick. And since they're a trivial cheaper and the smaller hole is easier to drill, the 3/16-in. size is commonly the better pick. If you're having problem with the 3/16-in. screws snapping off considering the concrete is besides hard, switch to stronger i/4-in. diameter screws instead. You lot could likewise keep some 1/4-in. screws handy in case you strip out the hole for a 3/16-in. spiral. Switch to 1/4-in. screws for heavy-duty piece of work similar securing a wall cabinet to a concrete or cake wall, or supporting shelving that will hold a lot of weight.

four / 8

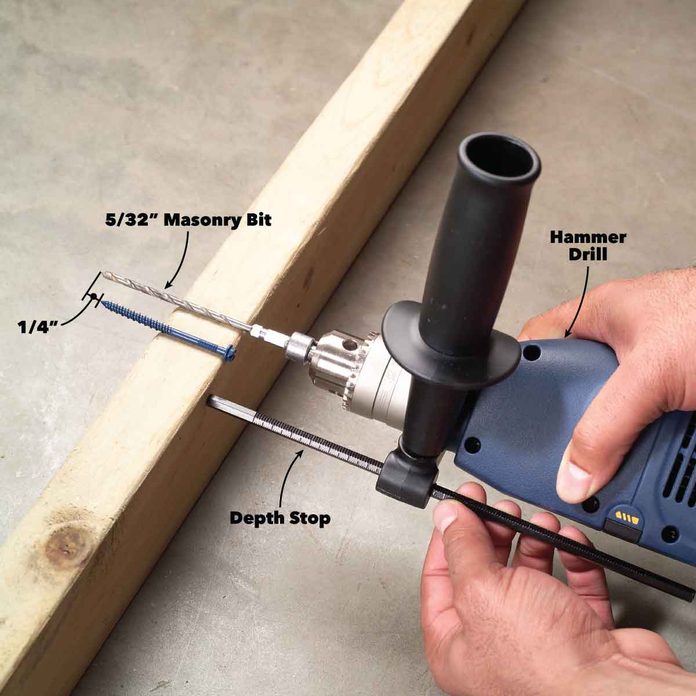

Apply a Hammer Drill

In some less dense materials like soft brick, you tin can drill pilot holes using a carbide-tipped bit in a regular drill. Simply in most cases, y'all'll demand a hammer drill. Corded hammer drills cost $65 to $400, or y'all tin buy a cordless model starting at $230. You tin can likewise rent hammer drills for about $35 per day.

Precisely sized carbide-tipped bits are ofttimes included with packs of screws, or you can purchase ane separately. Match the scrap to the size screw you lot're using: 5/32-in. bit for 3/16-in. screws and 3/xvi-in. diameter scrap for 1/iv-in. Keep a spare bit on hand, since the tip can article of clothing out chop-chop in some hard materials, resulting in a hole that'south too small-scale. One indication of a worn fleck is screws that are difficult or impossible to bulldoze completely.

Shut-Up of a Concrete Scrap

Concrete bits have a super-hard carbide tips.

5 / eight

Apply Hex Head Screws Where Advent Isn't an Upshot

Concrete screws are bachelor with either apartment head Phillips or hex heads. In situations where the spiral head must be affluent to the surface (furring strips under drywall), or where a Phillips head would await nicer, apply the Phillips head screws. Otherwise, always option the hex head screws. The positive date of the hex bit makes them easier to drive (see photograph, p. 35).You'll need a 1/4-in. hex driver for the 3/sixteen-in. screws and a 5/16-in. hex head commuter for the thicker 1/4-in. screws.

When you're using Phillips caput screws, keep actress No. 2 (No. three for i/4-in. screws) Phillips head $.25 on paw. The hardened screws vesture out bits speedily.

Screw Heads and Usage

Bulldoze Phillips caput screws where a flush surface is required and where a Phillips head would look better. Otherwise employ hex head screws.

half-dozen / eight

Drill With a Firm Hand and Maintain Steady Pressure

Good technique is essential for driving concrete screws. Not enough downward pressure and the scrap could slip off the head, peculiarly if yous're using Phillips head screws. For the best results, keep abiding pressure on the screw and run the drill at slow to medium speed.

It takes a low-cal bear on to avoid snapping screws. Heavy-duty drills work best considering they can maintain a steady slow speed. Stop every bit soon as the screw is affluent to the surface and your material is firmly attached. Driving at high speeds results in overdriving the screw and can strip the threads or break off the head. You'll develop a experience for the correct amount of speed after driving a few screws.

Stopping Bespeak

Ease off the driving speed equally the screw head nears the surface.

7 / 8

Utilize Two Drills or Buy an Installation Kit to Speed up the Job

Install the masonry bit in your hammer drill and a driver bit in a variable speed drill. And then yous won't have to switch bits constantly. Some other option is to buy an installation tool. It allows yous to switch quickly from drilling to driving mode and back again, and includes Phillips and hex head bits to drive both 3/16-in. and i/4-in. screws. We institute an installation kit alongside the physical screws at the home centre.

Shut-Up of Drill/Drive Kit

The kit contains a carbide-tipped scrap (replaceable) a hex driver and a Phillips driver.

8 / 8

Go along a Handful of Plastic Anchors in Case of Strip-Out

Occasionally the threads of a screw won't grip and the screw will spin in the hole. Ordinarily you can just abandon this hole and drive another screw a short altitude away. Simply if relocating the screw isn't a good pick, simply enlarge the hole and sideslip in a plastic ballast. And then bulldoze the physical spiral into the ballast.

Sleeve Anchors for Concrete Block

Fastening heavy items to concrete cake is simple if you lot use the correct tools and fasteners. Where most people mess up is in thinking they can use plastic anchors. Uh, no. At the very least you should use a lag shield, but even then, you tin can use that type of anchor only when mounting to one of the three solid sections of the block.

Sleeve anchors are a better option considering they work in the solid and hollow sections of the block, too every bit the mortar joints. Here are two important tips when y'all're installing sleeve anchors.

1. Leaving drilling grit in the hole will reduce the fastener's holding power. So remove it with a vacuum or blower. A baby'southward ear syringe (about $5 at any drugstore) works swell for this (keep ane in your toolbox). Only shove information technology into the hole and puff out the dust.

two. Protect the commodities threads by unscrewing the nut until it extends slightly past the bolt threads. Then bulldoze it home with light hammer blows.

Originally Published: September 13, 2019

Source: https://www.familyhandyman.com/list/drilling-concrete-and-installing-fasteners/

0 Response to "When Fastening a Heavy Item to Brick, What Is the Most Important Step?"

Post a Comment